Features:

High performance model with strong resistance.

In order to facilitate pipe distribution and operation, the vacuum pump connection valve and vacuum gauge are located at the front operating panel

Double doors made of tempered glass doors and polycarbonate for their protective effect.

The use of heat-resistant fluorine rubber gasket, durability, strong air tightness

In addition to easy to confirm the PV and SV two-stage disy of measured values and set values, it also uses the disy to prevent excessive temperature rise. On the basis of the V series, all the air receiving parts are made of resistant stainless steel, fluorine rubber, ceramic coating, etc.(not explosion-proof structure)

Specifications:

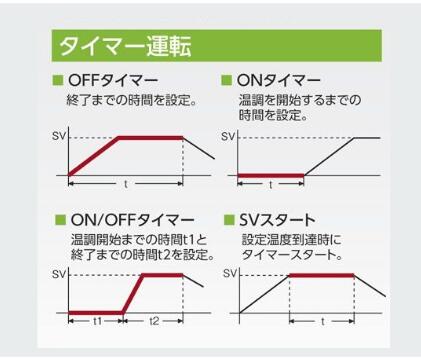

Additional functions: timer function (ON,OFF,ON,OFF timer,SV start)

Sensor :K thermocouple x 2 (temperature control, prevent excessive rise with 1 each)

Safety device: prevent excessive rise function (digital set), self-diagnosis function (heater break detection, sensor abnormal detection), overcurrent circuit breaker

Material

▼ External installation: Baked steel coating

▼ Interior :SUS304 resistance ceramic coating

▼ Shelf: aluminum resistant ceramic coating

▼ Piping, joint :SUS304 resistance ceramic coating

▼ Valve, vacuum gauge: stainless steel (SUS316,PTFE)

▼ Door seal: Fluorine rubber

▼ Observation window: tempered glass (12mm thick), polycarbonate protection te

Length of power cord :2.5m

Accessories: shelf ×2 pieces

Heating mode: tank heating mode

Temperature setting range :40~220°C

Vacuum range :0.1~101kPa

Control mode :PID control · SSR output

Valve diameter: outer diameter φ13mm

Specifications::

▼(sus316, ptfe)——

▼ Leaf gasket: fluorine rubber

▼観察窓:強化ガラス(厚さ12毫米)・ポリカーボネート製保護板—

:2.5m——

Payment products: shed board ×2

Heating mode: FOU body heating mode

Temperature setting: 40 ~ 220℃

Use vacuum: 0.1 ~ 101kPa

刷机:刷机:刷机

φ13mm——

【 Specification sheet 】

※ It takes about 18 days to ship from Japan in case of storage in Japan